Renewable Energy Insights

AraBat: Pioneering Sustainable Lithium-Ion Battery Recycling for a Renewable Future

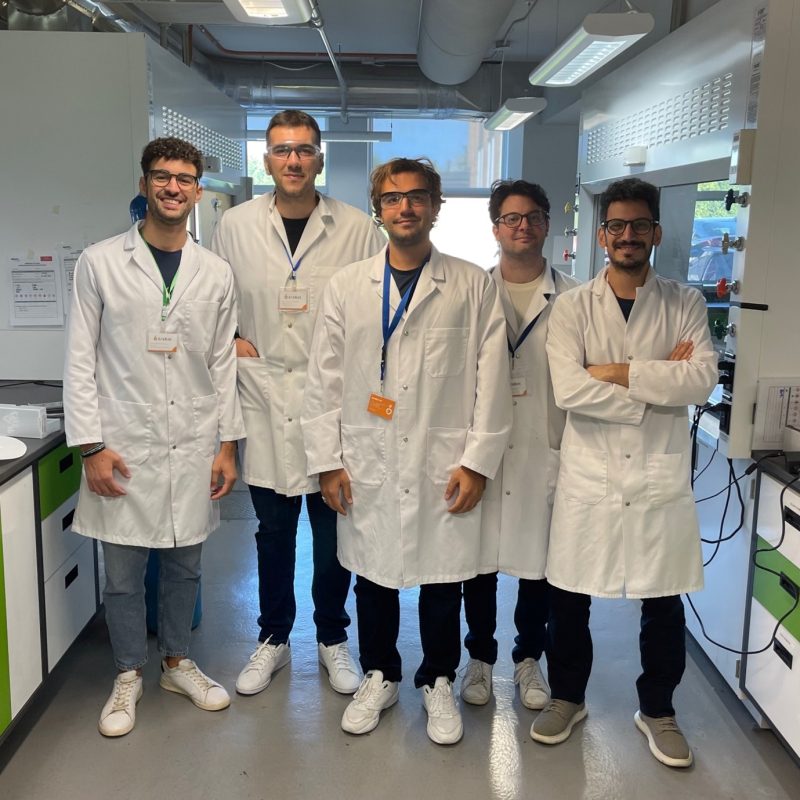

Written for the Renewable Energy Institute (REI) by Leonardo Binetti and Raffaele Nacchiero, AraBat

The Renewable Energy Institute is pleased to work with leading organisations including the United Nations Environment Programme, renowned university researchers and key industry players to disseminate knowledge globally through accredited training courses, webinars, conferences and technical articles. AraBat is an international organisation which is revolutionising the way we recycle batteries; their CTO and CEO have written this article exclusively for the Institute.

The world is witnessing an unprecedented surge in renewable energy adoption, and lithium-ion batteries play a pivotal role in this transition. However, the increasing demand for these batteries also brings forth the challenge of their end-of-life management. AraBat, a revolutionary startup from Apulia (South Italy), is addressing this issue head-on with its innovative and sustainable recycling technology. AraBat has developed an innovative process to recycle spent lithium-ion batteries efficiently and sustainably. The company recycles waste lithium-ion batteries by reusing fruit and vegetable waste, such as orange peels. This process allows AraBat to recover valuable metals from spent batteries without causing pollution.

Lithium-ion batteries have become the dominant energy storage technology for large-scale plants, ensuring a reliable supply of renewable energy. They enable energy from renewables, like solar and wind, to be stored and then released when power is needed the most. This capability is crucial in managing the intermittent nature of renewable energy sources and ensuring a steady power supply. The demand for lithium-ion batteries is skyrocketing, especially with the rise of electric vehicles. In 2030, there will be more than 1.2 million tons of lithium batteries destined for recycling. However, the increased production and use of these batteries have significant environmental implications, including the depletion of natural resources and the challenge of managing spent batteries. According to Nano Energy, one single lithium battery can emit over 100 toxic gases, including carbon monoxide (CO).

The startup’s mission aligns with the circular economy principles, aiming to manage and valorize hazardous waste and industrial by-products sustainably. AraBat co-founders are young Apulian professionals with skills mainly in the field of management engineering, corporate finance and marketing, chemistry and materials engineering: Raffaele Nacchiero (CEO), Leonardo Renna (CFO), Giovanni Miccolis (COO), Leonardo Binetti (CTO), Vincenzo Scarano (CMO).

AraBat’s recycling process, named “AraMet”, addresses the environmental issues associated with spent battery management and contributes to solving the complex supply issues of critical raw materials. This technology is a green hydrometallurgical process including three different phases: i) a mechanical pre-treatment of the input batteries which produces copper, aluminum and black mass; ii) a green leaching on black mass, based on the use of water, organic acids (e.g. citric acid) and biomass mix (fruit or vegetable waste and by-products, such as orange peels); iii) selective precipitations to recover high value raw materials in the form of hydroxides (nickel, manganese, cobalt) and carbonates (lithium). This technology has several advantages over pyrometallurgical processes (using large furnaces and very high temperatures) or conventional hydrometallurgical processes (using inorganic and toxic reagents and acids). In addition to being more sustainable and circular, thanks to the use of acids and organic waste, AraMet is also advantageous in terms of energy impact and economic costs: it uses less water, a chemical treatment duration of 1 hour and temperatures below 80°C.

Thanks to its technology, AraBat has been named “the Apulian Miracle” and “the most awarded startup in Italy,” having won numerous awards and competitions, such as ENI Award 2022 (ENI Joule Entrepreneurship, conferred by the top management of ENI and by the President of the Italian Republic Sergio Mattarella at Quirinale), Start Cup Puglia 2022, Premio Nazionale dell’Innovazione 2022 (Section Cleantech & Energy), and Canada-Italy Innovation Award 2023. StartUs Insights includes AraBat among the top 10 battery remanufacturing startups in the world. AraMet has been defined by some experts as “one of the most sustainable battery recycling processes in the world.” This is due to the fact that such a technology makes it possible to solve numerous grand challenges and global problems, creating an unprecedented connection between biomass and batteries, and also between agriculture and the electricity transition.

Having already validated the technology in laboratory and pre-industrial environments, AraBat’s next objective will be that of industrialization (TRL 8/9) through the design and construction of a pilot plant, with a recycling capacity of approximately 10/200 tons of lithium batteries per year. For this plan, AraBat is discussing with various Italian investment funds to close a seed investment round and with famous international corporates interested in the technology in its possession.

AraBat Srl’s innovative and sustainable approach to lithium-ion battery recycling is a game-changer in the renewable energy sector. By closing the loop in the battery life cycle, the company is paving the way for a more sustainable future. As we continue to embrace renewable energy, companies like AraBat are essential in ensuring that this transition is sustainable and beneficial for our planet.

Learn more about batteries and their role in the global energy transition with our accredited Energy Storage course. Study as a standalone course or as part of one of our Expert Certificates to make the next step in your renewable energy career.

Read Next: What is the waste-to-energy market outlook?